Architectural Decorative Metal Mesh: Weaving Methods & Structures

Truji Architectural Mesh Co. specializes in the precision manufacturing and design of metal decorative wire mesh for architectural use. We offer woven mesh, crimped mesh, ring coil drapery, chain link curtains, spiral mesh, metallic scale curtains, cable webnet, wire conveyor belts, and more. Our products feature solid structure, attractive appearance, and lightweight design. See below for detailed information.

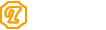

Woven Wire Mesh – Plain, Twill, and Dutch Weave Types

Woven wire mesh is produced by interlacing stainless steel, brass, or copper wires in patterns such as plain weave, twill weave, and Dutch weave. Known for its uniform openings and high tensile strength, it is widely used in architectural panels, filtration systems, safety screens, and interior partitions. Available in fine mesh counts from 10 to 500 mesh, it offers precision and stability for decorative and industrial applications.

- Plain Weave: The most basic and common type, where each warp wire crosses over and under each weft wire. It offers a balanced structure with uniform openings for general applications.

- Twill Weave: Each warp wire goes over two and under two weft wires, allowing for stronger mesh with finer openings. Ideal for higher strength and finer filtration requirements.

- Dutch Weave (Plain or Twill): Features thick warp wires spaced wide with fine, tightly packed weft wires. Used mainly in fine filtration where strength and precision are essential.

- Characteristics: Flat surface with even apertures. Offers good mechanical strength and is available in fine mesh counts from 10 to 500 for varied applications.

- Applications: Used in filtration, sieving, shielding, and decoration. Common in industries like chemical processing, mining, and interior architectural design.

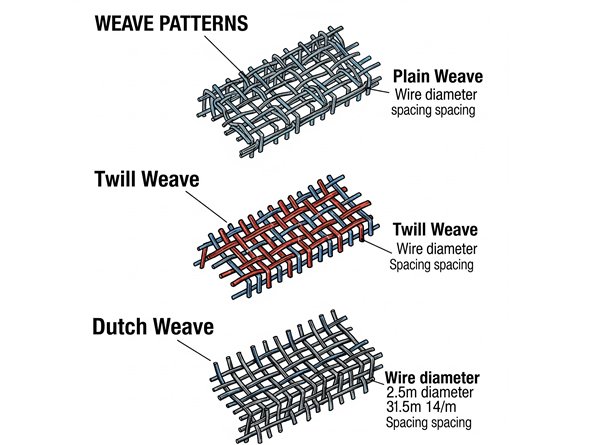

Crimped Wire Mesh – Locking Structure with Pre-Crimped Wires

Crimped wire mesh features pre-crimped wires woven into stable patterns like double crimp, lock crimp, intercrimp, and flat top. Commonly made from stainless steel or galvanized steel, this rigid mesh is ideal for decorative grilles, infill panels, fencing, mining screens, and architectural cladding. Mesh openings range from 1 mm to 100 mm, providing versatility and strength for both functional and design purposes.

- Pre-Crimped Weave: Wires are crimped before weaving to lock positions. This method increases mesh stability and keeps wires fixed under tension or pressure.

- Types: Common types include Double Crimp, Lock Crimp, Flat Top, and Intercrimp. Each offers varying rigidity and visual patterns depending on structural or decorative needs.

- Characteristics: Excellent rigidity and dimensional accuracy. Crimped wires prevent movement under load. Aperture sizes typically range from 1 mm up to 100 mm.

- Applications: Widely used in architectural grilles, safety infill panels, mining screens, and durable fencing in both industrial and decorative settings.

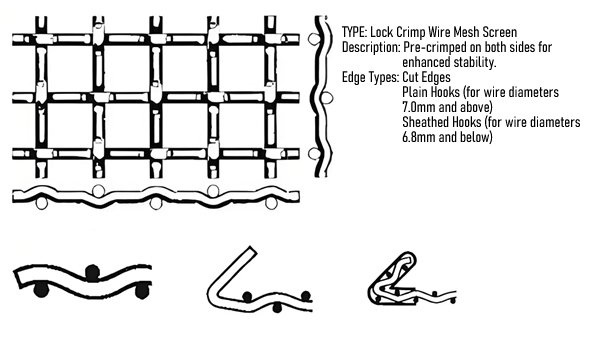

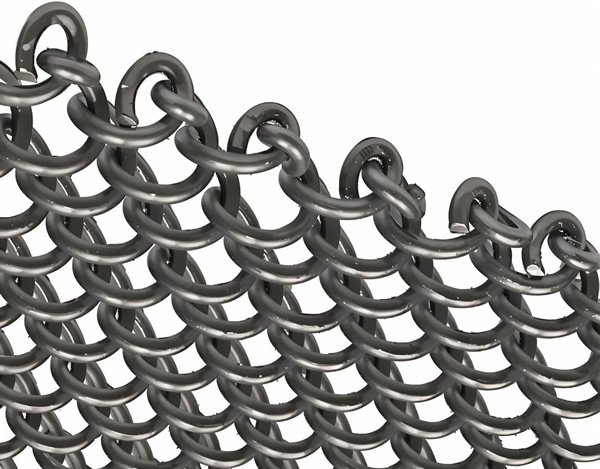

Ring Mesh Coil Drapery – Chainmail-Style Flexible Metal Fabric

Ring mesh coil drapery is made from interconnected metal rings in a chainmail pattern, offering a flexible and fire-resistant structure. Available with butted or welded rings, this mesh is widely used in hotel lobbies, stage backdrops, partition walls, and architectural curtain systems. Ring diameters typically range from 6 mm to 20 mm, with wire thickness from 0.8 mm to 2.0 mm, creating an elegant metallic texture for interiors.

- Structure Type: Chainmail (Butted or Welded Rings): Metal rings interlock in a 4-in-1 pattern. Rings may be open (butted) or closed (welded) depending on strength requirements.

- Ring Diameter: Common ring diameters range from 6 mm to 20 mm, with variations chosen based on visual density and application demands.

- Ring Wire Thickness: Ring wire thickness typically ranges from 0.8 mm to 2.0 mm, affecting both the mesh's weight and durability.

- Characteristics: Flexible and free-hanging design. Easily installed using curtain tracks, rails, or custom fixed support frames.

- Applications: Suitable for room dividers, fire-resistant drapery, and theatrical or event stage backgrounds.

Chain Link Metal Curtain – Interlinked Wire or Hooked Mesh Curtains

Chain link metal curtains are formed from interlocking metal loops or hooked chains, creating a lightweight and mobile mesh. These curtains are used in exhibition halls, space dividers, window treatments, and commercial interiors. Constructed from aluminum or stainless steel, the link size usually ranges from 8 mm to 20 mm, making them ideal for airflow, light filtration, and visual separation.

- Structure Type: Linked Hooked Loops or Chains: Made by interlocking S-shaped or oval metal links. Available in both flat and round wire styles.

- Link Sizes: Common link widths range from 8 mm to 20 mm, with thicknesses from 0.6 mm to 2.0 mm.

- Characteristics: Lightweight and easy to move. Maintains airflow and natural light transmission in open designs.

- Applications: Used for window coverings, space dividers, and decorative displays in galleries or exhibitions.

Spiral Pattern Architectural Mesh – Helical Spirals and Cross Rods

Spiral mesh features flat or round spiral wires connected with straight rods, forming a semi-rigid structure. Commonly used in building facades, sunscreens, railing infills, and decorative ceilings, this type of mesh offers both strength and visual transparency. Spiral widths range from 3 mm to 20 mm, with variable rod pitches up to 30 mm, making it suitable for modern architectural designs.

- Spiral Wires + Rods System: Helical spirals interlock and are woven with straight rods. Spirals may be round or flat depending on design needs.

- Spiral Dimensions: Spiral widths range from 3 mm to 20 mm, with rod pitch between 3 mm and 30 mm.

- Characteristics: Semi-rigid mesh structure spans wide areas and delivers a modern, industrial aesthetic.

- Applications: Commonly used for facade cladding, solar shading, railings, and architectural ceiling treatments.

Metallic Scale Drapery Curtains – Overlapping Metal Plate Structure

Metallic scale drapery is designed with small overlapping metal scales, similar to fish or armor plating. It creates a shimmering, textured surface used in wall coverings, high-end interiors, exhibition spaces, and window decor. Scales typically range from 5 mm to 30 mm wide, and are attached to flexible backings with rings or wire supports. Ideal for applications requiring both aesthetics and light control.

- Overlapping Metal Scales: Small convex or flat metal plates (scales) are joined with rings and attached to mesh backing or chain supports.

- Scale Dimensions: Scale width ranges from 5 mm to 30 mm, with thickness between 0.3 mm and 1.0 mm.

- Characteristics: Produces a shimmering, fish-scale effect; the structure is lightweight, flexible, and semi-transparent.

- Applications: Commonly used for wall decoration, fashion installations, and semi-transparent interior partitions.

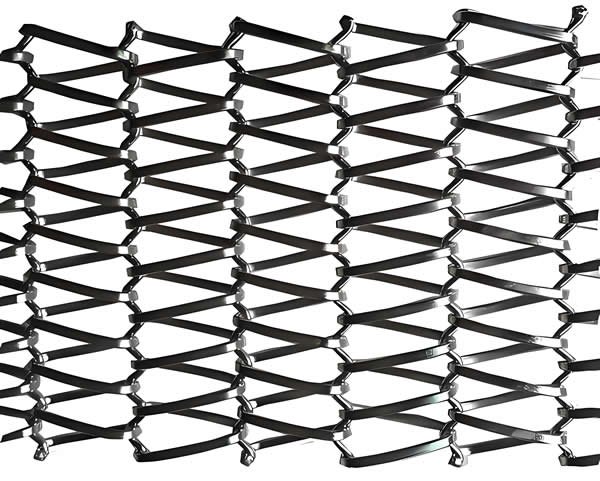

Cable Mesh Webnet – Stainless Steel Rope Mesh with Ferrules or Knots

Cable mesh, also called Webnet, is constructed from stainless steel cables connected by ferrules or knots. It forms a flexible, diamond-shaped net structure ideal for balustrades, animal enclosures, green facades, and safety railings. Mesh openings range from 20 mm to 200 mm, and cable diameters from 1.2 mm to 4.0 mm, offering exceptional transparency, flexibility, and weather resistance.

- Handwoven (Knotted) or Ferrule Type: Stainless steel cables intersect diagonally, joined by hand knots or metal ferrules for secure mesh formation.

- Mesh Shape: Available in diamond or square patterns to suit design and function.

- Mesh Sizes: Standard sizes range from 20 × 20 mm to 200 × 200 mm, with cable diameters from 1.2 mm to 4.0 mm.

- Characteristics: Strong yet flexible and lightweight, offering high transparency and impact resistance.

- Applications: Ideal for zoo enclosures, balustrades, vertical gardens, and stair railings.

Wire Conveyor Belts – Balanced Spiral and Ladder Weave Belting

Wire conveyor belts are manufactured using spiral or ladder weave methods with stainless steel or carbon steel wire. These belts are essential for industrial processing, food production, drying systems, and heat treatment lines. Structures include balanced spiral weave, compound weave, and ladder belts, with wire diameters from 1 mm to 5 mm and customizable pitch and width for optimized performance.

- Balanced Spiral Weave: Spirals alternate left and right, connected by straight rods for stability and strength in motion.

- Ladder Belt: Made of U-shaped wires joined by cross rods, creating an open, flat, and lightweight mesh structure.

- Compound Balanced Weave: Features tightly packed multiple spirals with interwoven rods, suitable for heavier-duty industrial tasks.

- Wire Sizes: Wire diameters range from 1 mm to 5 mm, with pitch options from 5 mm to 50 mm.

- Characteristics: Heat-resistant and load-bearing, supports precise movement; available with welded, chain-linked, or hook edges.

- Applications: Used in food baking, heat treatment, industrial drying, and freezing processes.